Computed tomography is used in industrial manufacturing applications. CT scanning is used to produce three dimensional images of internal and external part features. Using this technology companies can break down components without destroying them. Manufacturing applications include flaw detection, metrology, reverse engineering, failure analysis, and assembly analysis. These machines allow for the engineers to see how parts connect, identify failures, and see how they operate. The ability to look at slices of internal and external workings of a part allow for the pin pointing of areas of concern. By knowing exactly where an issue is occurring the proper steps can be taken to fix it. This usually allows for engineers to save time and money by immediately identifying an issue and then accurately diagnosing how it should be fixed. There are two types of industrial CT machinery line beam scanners and cone beam scanners.

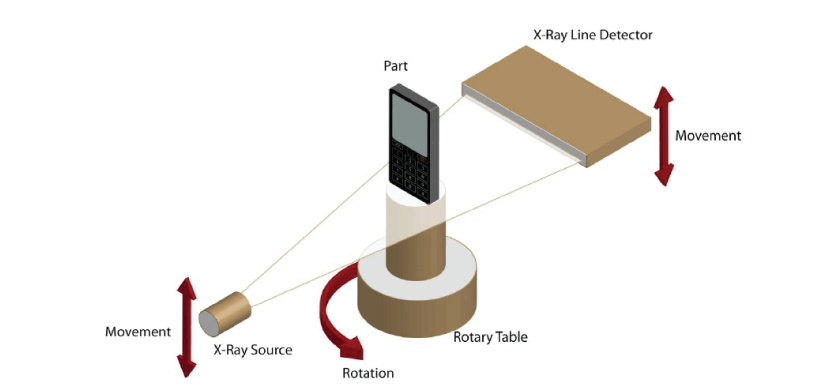

Line Beam Scanner

Line beam scanners were the first to be used for industrial manufacturing purposes. X-rays are produced and the beam is collimated to create a line. The X-ray line beam is then translated across the part and data is collected by the detector. The data is then reconstructed to create a 3-D Volume rendering of the part.

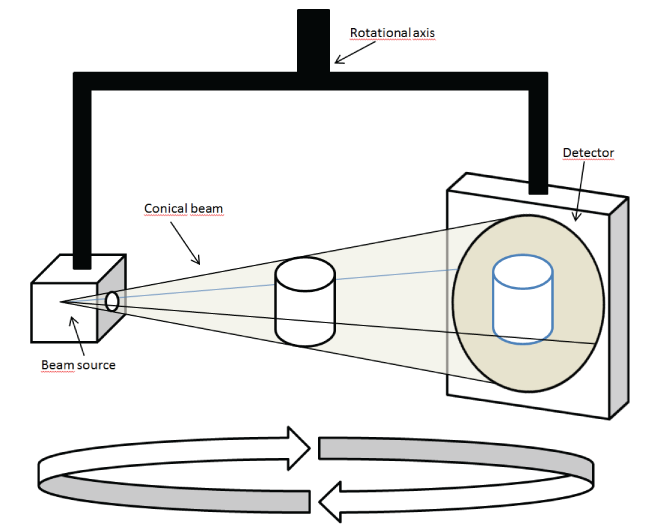

Cone Beam Scanner

Cone beam scanners utilize a rotary table. The part is placed on the table and the x-ray emitting cone takes around 1300 two dimensional images. These images are collected by the detector and a computer combines them creating a three dimensional image of its internal and external structures.